Introduction to Faceting Mini Course

Yield Optimization vs. Aesthetics

Picture this: You have a stunning piece of aquamarine rough worth thousands of dollars. Do you cut it for maximum weight retention to preserve its value, or do you sacrifice material to achieve perfect brilliance? This fundamental question haunts every serious gemstone faceter.

The tension between yield optimization and aesthetic perfection represents one of the most challenging decisions in gemstone cutting. Every faceter—from weekend hobbyists to professional cutters—must navigate this delicate balance. The choices you make can mean the difference between a profitable cut and a costly mistake.

In this article, you'll learn:

- What yield means and why it's crucial for both cutters and investors

- Proven strategies to maximize weight retention from irregular rough stones

- How to balance material preservation against optical performance

- When to prioritize yield versus when aesthetics should win

- Real-world examples that demonstrate smart decision-making

Understanding Yield: The Foundation of Smart Cutting

What Is Gemstone Faceting Yield?

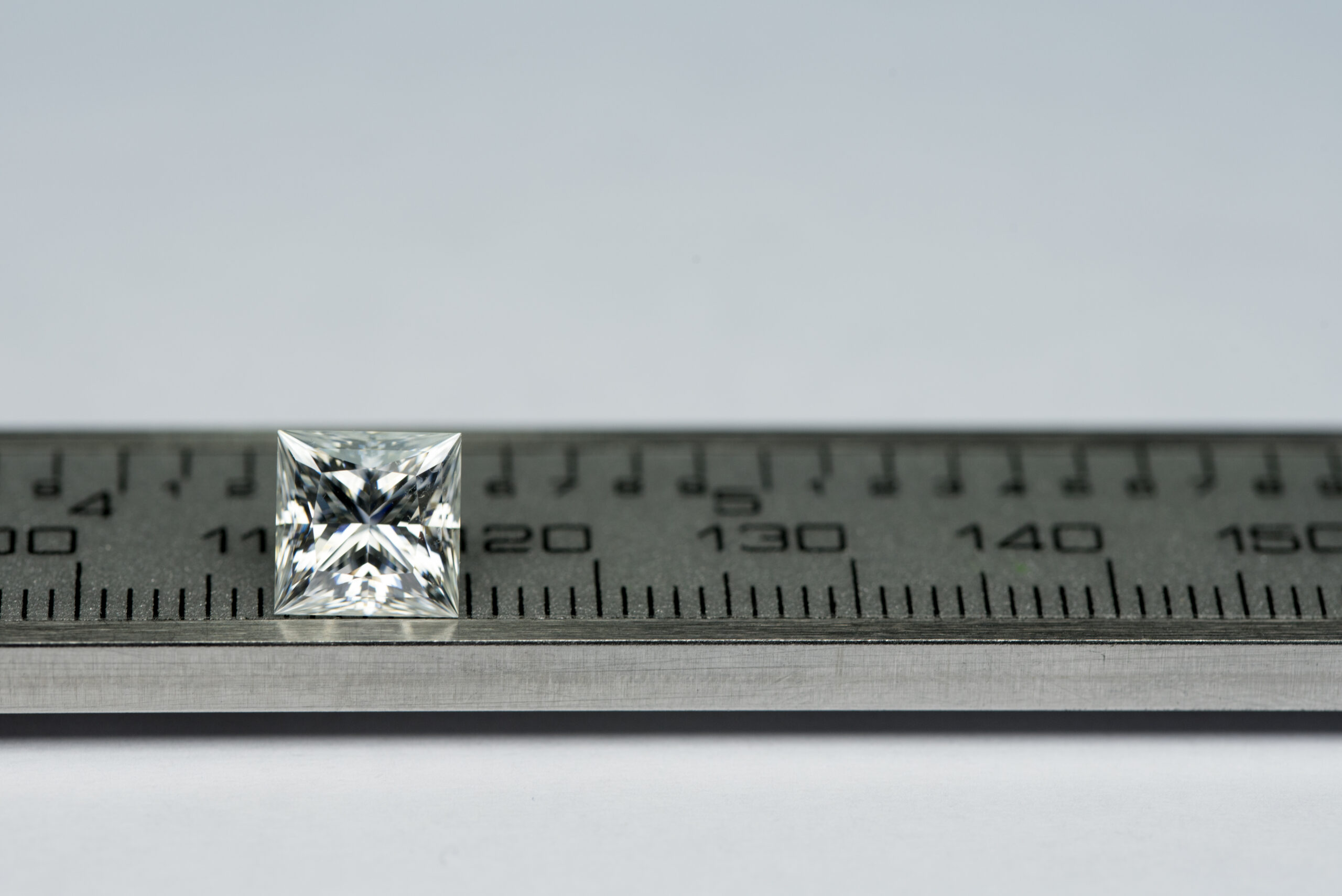

Yield refers to the percentage of original rough material that becomes the finished gemstone. If you start with a 10-carat piece of rough and end up with a 3-carat finished gem, your yield is 30%. This seemingly simple calculation drives countless decisions in the faceting world.

Most faceters achieve yields between 25% and 33% with custom cutting. Factory operations typically see lower yields of 15% to 25% due to standardized processes that prioritize speed over material conservation. However, these percentages can vary dramatically based on the rough quality and cutting strategy.

Why Yield Matters to Cutters

For professional faceters, yield directly impacts profitability. Consider aquamarine rough selling for $100 per carat. A 30% yield means you need to pay for roughly 3.3 carats of rough to produce each finished carat. Poor yield planning can quickly turn a profitable project into a financial disaster.

Time investment also factors heavily into yield considerations. As one experienced faceter notes, "If the value of the finished gem is too low, cutting it isn't profitable for a professional." Even hobbyists feel this pressure—nobody wants to spend dozens of hours on a project that yields disappointing results.

The Investor's Perspective

Investors and collectors view yield through a different lens. They're often willing to accept lower yields if it means preserving exceptional characteristics like color or clarity. A rare Padparadscha sapphire might justify aggressive material removal to eliminate inclusions, even if yield drops below 20%.

However, smart investors also understand that excessive material loss can destroy value. The key lies in understanding when additional cutting improves the gem's per-carat value enough to justify the weight loss.

Maximizing Yield from Irregular Rough

The Power of Cutting by Sight

Traditional faceting methods rely heavily on predetermined angles and measurements. But these rigid approaches often waste material when dealing with irregular rough. The "Easy Way" approach introduced by Don Clark in his book "Modern Faceting - The Easy Way" revolutionizes this approach by emphasizing visual assessment over mathematical precision.

Instead of forcing rough into standardized proportions, cutting by sight allows faceters to work with the natural shape of the material. You cut the outline first, establish a level girdle using a single angle, then finish with main facets—all while adapting to the unique characteristics of each piece.

This flexibility can dramatically improve yields. One design can accommodate length-to-width ratios from 1.1 to 1.8 to one, eliminating the need to cut away material to meet specific proportions.

Strategic Girdle Placement

Girdle placement represents one of the most powerful yield optimization tools. By positioning the girdle to maximize both crown and pavilion material, skilled faceters can often improve yields by 10% or more.

The key insight is that girdle placement isn't fixed. If you encounter a flaw near one end of the rough, you can shift the girdle position to exclude the problematic area while maintaining good proportions. This approach requires experience to judge crown angles that will work with the available material.

Working with Natural Crystal Forms

Sometimes the biggest yield improvements come from working with, rather than against, natural crystal structures. Consider this surprising approach: when cutting an aquamarine crystal with a growth line, the optimal strategy might be cutting along that line at a 45-degree angle rather than straight across.

This technique serves multiple purposes. It removes flaws that follow the growth pattern, pre-forms pavilion points for multiple gems, and can yield significantly larger finished stones. What appears to be an unconventional cut often produces better results than traditional approaches.

Flexible Design Selection

Different gem designs offer vastly different yields from the same piece of rough. Barion cuts, for example, can accommodate deeper rough that might not work well for standard cuts. The ability to switch between designs based on rough characteristics can improve yields substantially.

Step-cut crowns typically yield better than brilliant-cut crowns on fancy shapes. Computer studies consistently show 5% to 15% brilliance improvements when switching from brilliant to step-cut crowns on non-round shapes. This combination of better yield and improved performance makes step cuts attractive for many applications.

The Brilliance vs. Weight Trade-off

Understanding Optical Performance

Maximum brilliance requires specific geometric relationships between crown and pavilion angles. For most colored stones, pavilion main angles of 42 degrees provide optimal light return. However, achieving these ideal angles often requires removing additional material.

Crown angles offer more flexibility. While shallow crowns around 26 degrees maximize light return, they also cause gems to "dump light" when tilted slightly. Higher crown angles sacrifice some brilliance but improve light retention across viewing angles. This trade-off becomes crucial when working with limited crown material.

The 42-Degree Rule

Here's a surprising insight from computer modeling: "The greater the amount of the pavilion is cut at 42 degrees, or very close to it, the brighter the finished gem will be." This principle suggests that yield optimization should focus on preserving pavilion material while being more flexible with crown proportions.

This approach challenges traditional thinking that treats all gem proportions as equally important. By prioritizing pavilion geometry, faceters can achieve excellent brilliance while maximizing material retention.

Quality vs. Quantity Decisions

Sometimes the choice between yield and aesthetics isn't subtle. Consider a piece of rough with an inclusion near the center. Removing it completely might require cutting away 20% to 30% of the material to maintain symmetry. Yet leaving it in place might only reduce the gem's value by 5% to 10%.

The math often favors keeping minor inclusions, especially when they're positioned under crown facets where visibility is minimal. However, inclusions in the pavilion center create a "stab in the heart" effect where reflections multiply the apparent size of the flaw.

When to Prioritize Yield vs. Aesthetics

Rare Material Scenarios

With exceptionally rare or expensive materials, yield typically takes priority. If you're working with $1,000-per-carat rough, every fraction of a carat counts. Even significant compromises in cut quality may be justified if they preserve substantial weight.

Paraiba tourmaline, jadeite, and fine Kashmir sapphire often fall into this category. Professional cutters working with such materials focus primarily on inclusion removal and basic proportional correctness, accepting that perfect optical performance is a secondary concern.

High-Volume Commercial Cutting

Factory cutting operations almost always prioritize yield over perfection. When processing hundreds of carats of material, consistent yields matter more than exceptional individual stones. These operations typically use standardized designs that maximize throughput while maintaining acceptable quality levels.

Even custom cutters working with commercial-grade material often emphasize yield. If the rough costs $10 per carat and the finished gem sells for $40 per carat, maximizing weight retention provides better returns than pursuing perfect proportions.

Fine Quality Material

Exceptional color and clarity justify more aggressive cutting approaches. When working with investment-grade material, the goal shifts from weight retention to value optimization. A perfectly cut 2-carat gem might be worth more than a poorly cut 3-carat stone from the same rough.

This principle particularly applies to diamonds, where cut quality dramatically affects value. However, colored stones with exceptional color saturation or clarity also benefit from prioritizing optical performance over yield.

Collector and Designer Markets

Some markets consistently reward quality over quantity. High-end jewelry designers often prefer smaller, perfectly cut gems over larger stones with compromised proportions. Understanding your target market helps determine the appropriate balance point.

Custom cutting for collectors often emphasizes unusual designs or perfect execution over yield concerns. These clients typically understand that exceptional results require material sacrifice and price their purchases accordingly.

Inclusion Management Decisions

Inclusion management represents the most common yield-versus-aesthetics decision point. Small veils that are barely visible often aren't worth removing, especially if they're positioned under crown facets. However, fractures almost always require removal due to structural weakness.

The location of inclusions dramatically affects this calculation. An inclusion near the girdle under a crown facet has minimal impact on appearance or value. The same inclusion in the pavilion center would be highly visible and should probably be removed despite the yield impact.

Dark-colored gems often hide inclusions effectively. Most red garnets contain black inclusions that are visible under magnification but disappear to the naked eye due to the dark body color. These inclusions rarely justify material removal.

Real-World Case Studies

The Aquamarine Decision

Consider a high-quality aquamarine crystal with a flaw running at 45 degrees through one section. The conventional approach would be cutting straight across, removing the entire flawed section. However, cutting along the flaw line at 45 degrees serves multiple purposes: it removes the flaw, pre-forms pavilion points, and yields larger finished stones.

This approach demonstrates how understanding crystal structure and flaw patterns can turn apparent problems into advantages. The angled cut that removes the flaw also optimizes the cutting geometry for better yields.

The Emerald Compromise

Emeralds present unique challenges because fractures and inclusions are nearly universal. Most emerald cutters simply cut for yield, accepting that some inclusions will remain. The rationale is simple: emerald's value lies primarily in color, and the loss from removing every flaw would exceed the improvement from perfect clarity.

However, structural fractures still require removal even in emeralds. The key is distinguishing between cosmetic inclusions that can remain and structural weaknesses that must be addressed.

The Designer's Choice

A jewelry designer commissioning a custom piece might prefer a 1.5-carat perfectly proportioned stone over a 2.2-carat stone with compromised angles. Understanding these preferences helps determine when to prioritize aesthetics over yield.

The premium for perfect cutting can be substantial in designer markets. A perfectly cut stone might command 50% higher per-carat pricing, making yield sacrifices economically justified.

Summary: Making Smart Cutting Decisions

The balance between yield optimization and aesthetic perfection requires careful consideration of multiple factors. Material cost, target market, inclusion patterns, and crystal structure all influence the optimal approach.

Key takeaways for successful faceting decisions:

- Yield typically matters most with rare, expensive materials where every carat counts

- Cutting by sight and flexible girdle placement can improve yields by 10% or more

- The 42-degree pavilion rule allows crown flexibility while maintaining brilliance

- Minor inclusions under crown facets often aren't worth removing

- Market understanding determines whether yield or aesthetics should take priority

Success in faceting comes from recognizing that there's rarely a single "correct" approach. The best cutters develop judgment through experience, learning when to prioritize material retention and when to sacrifice weight for exceptional beauty. Whether you're a hobbyist or professional, understanding these trade-offs will improve both your results and satisfaction with the craft.

International Gem Society

Never Stop Learning

When you join the IGS community, you get trusted diamond & gemstone information when you need it.

Get Gemology Insights

Get started with the International Gem Society’s free guide to gemstone identification. Join our weekly newsletter & get a free copy of the Gem ID Checklist!