Introduction to Faceting Mini Course

Technological Advances in Faceting

For thousands of years, gem cutting was purely an art form passed down through generations of skilled craftsmen. Masters would spend decades learning to read the crystal structure of rough stones, understanding how light would dance through carefully placed facets. Today, this ancient craft is experiencing a technological revolution that's transforming how we cut, polish, and perfect gemstones.

Modern faceting combines traditional artistry with cutting-edge technology. Computer programs now predict exactly how light will behave in a finished stone before the first cut is made. Lasers can slice through the hardest diamonds with surgical precision. Robots work alongside human craftsmen to produce thousands of perfect gems daily.

This technological leap isn't replacing human skill—it's amplifying it. Today's gem cutters have tools their predecessors could never imagine, yet the fundamental goal remains the same: revealing the hidden fire within rough stone.

In this article, you'll discover:

- How computer software revolutionized gem design and eliminated guesswork

- Why laser cutting can slice diamonds faster than mechanical saws

- How 3D scanning reduces cutting waste by two-thirds

- Why robots can now cut 50,000 small gems per day

- How artificial intelligence is learning to grade gemstones better than human experts

CAD and Digital Modeling

The Software Revolution in Gem Design

Gone are the days when gem cutters relied solely on hand-drawn diagrams and decades of experience. Computer-aided design (CAD) has fundamentally transformed gemstone faceting from guesswork into precise science.

GemCad emerged as the first breakthrough program for PC systems. This software produces accurate faceting diagrams that cutters can take directly to their machines. No more trial and error—every angle is calculated for optimal light performance. The program runs on standard Windows computers, making professional-grade design tools accessible to cutters worldwide.

The newer GemCut Studio has become the industry standard. Professional cutters report using this $99 software for virtually every stone they cut. The program allows users to trial-cut virtually first, optimizing angles for better light return before touching the actual stone. This means fewer mistakes and better results for both amateur and professional cutters.

Predicting Light Performance Before Cutting

Perhaps the most remarkable advancement is GemRay technology, which uses ray tracing to predict exactly what a faceted gemstone will look like when finished. This software calculates how light will enter, bounce around inside, and exit the stone—all before making the first cut.

The combination of GemCad for creating cutting diagrams and GemRay for optical prediction gives cutters unprecedented confidence. They know their geometry will produce stones that sparkle exactly as intended. This eliminates the expensive trial-and-error process that traditionally consumed rough material and time.

Color Prediction Technology

Modern software goes beyond just predicting sparkle—it can forecast color appearance too. Advanced programs combine gemstones' absorption spectra with 3D modeling to show exactly what color the finished stone will display.

This breakthrough addresses a critical challenge in colored stone cutting. Cutters must achieve the best possible color while maximizing the stone's size and brilliance. DiamCalc software can model gemstones of specific colors by importing absorption spectra from databases or spectrometers.

The technology uses parametrical cuts—symmetrical designs determined by specific mathematical parameters. These cuts are available through online libraries, dramatically expanding creative possibilities for cutters worldwide.

Automated Jewelry Design Systems

Recent developments include computer modules that automatically design complex jewelry settings. These systems can arrange center stones, side stones, and accent stones using mathematical models that account for sizes, distances, prong dimensions, and even metal shrinkage during production.

Research shows these automated systems reduce design time by 67-70%. Tasks that traditionally took designers 87 minutes now complete in just 27 minutes. For complex pieces like cushion-cut centers with double halo arrangements, this time savings translates directly into cost savings and faster production.

Laser Cutting and Precision Improvements

Ultra-Precision Laser Technology

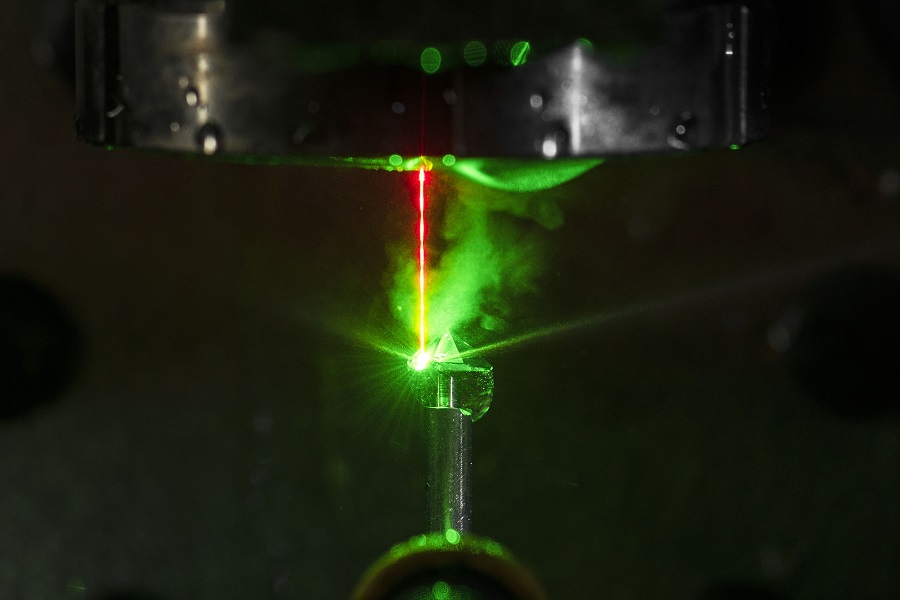

The most dramatic advancement in gem cutting comes from revolutionary water jet guided laser technology that uniquely combines green solid-state laser laser pulses with a hair-thin precision water jet, meeting ultra-high machining standards.

Unlike traditional mechanical cutting or conventional lasers, water jet guided laser technology solves critical issues that have plagued other cutting methods. The laser beam is guided by the thinnest water jet through total internal reflection, resulting in perfectly parallel kerf walls and tight cutting widths without thermal damage, taper, or contamination.

This represents a quantum leap in precision for materials like diamonds. The ingenious combination ensures the cutting zone stays cool and clean through continuous water application, making it remarkably gentle on even the hardest materials. While conventional laser beams have limited working distance and require constant refocusing, water jet guided lasers can be guided in a cylindrical shape without any taper over distances up to 10 centimeters.

The technology maintains perfect accuracy throughout the cutting process, capable of fast 3D cutting and shaping with micron precision on materials ranging from diamonds to delicate substrates, regardless of thickness or surface irregularities.

Revolutionary Diamond Cutting Speed

Modern laser systems have transformed diamond cutting with remarkable speed improvements. A 1.00-carat crystal can be laser-sawn in approximately 20 minutes, compared to 120 minutes for mechanical sawing. The laser cuts through grain obstacles that would stop mechanical saws.

Some breakthrough solutions enable grain-independent polishing, addressing one of diamond cutting's most challenging aspects. Traditional crystal orientation requirements that demanded intensive manual labor are eliminated.

3D Scanning and Waste Reduction

Advanced 3D scanning technology like the AICON SmartScan has revolutionized how cutters approach rough stones. This technology can minimize approximately two-thirds of traditional cutting waste, achieving higher prices through better material utilization.

The scanning identifies the best possible cut pattern for each source stone. It analyzes countless combinations of cutting shapes, proportions, and facet patterns that characterize colored gemstones. The 3D measurement data then guides fully automated polishing processes.

This technology is particularly valuable for small, irregularly shaped gemstones that are difficult to measure manually. Automated turn/tilt units fed by robots enable completely automated measuring procedures.

Computer-Controlled CNC Systems

Fully automated CNC gem faceting machines represent the latest evolution in precision cutting. Some systems can cut common shapes as well as special forms and frosted gems, performing both cutting and polishing in a single machine.

These systems eliminate the need to learn traditional faceting diagram reading. Operators simply open design files, adjust settings for size and cutting parameters, and initiate automated faceting. The machines use stepper motors for precise angle control and integral lifting mechanisms for enhanced processing quality.

Modern automated systems achieve remarkable production capacities. Computer-controlled equipment can process 60 pieces of 2mm gems or 20 pieces of 3mm+ gems, with some systems enabling individual operators to process up to 50,000 pieces per day.

Fully automated CNC gem faceting machine in action. Photo: 貓頭鷹藝術科技(Fukuro Art & Technology Co.)

Robotic Mass Production

The integration of robotics has created new possibilities for mass production while maintaining artisanal quality. The Jang 1024 robotic system can handle up to 56 small stones simultaneously, with daily capacities of 2,000-4,000 stones between 1.0-3.0mm in size.

The system maintains maximum tolerance of 0.05mm while performing the entire process from preforming to polishing under computer control. This precision rivals the best human craftsmen while operating at impossible speeds.

Future developments promise AI-driven robotics that learn from previous cutting experiences and adapt to different gemstone materials. Collaborative robots or "cobots" designed to work alongside human workers will preserve the unique blend of tradition and innovation.

Artificial Intelligence in Gem Grading

Computer vision systems now automatically classify gemstones and assess quality using advanced algorithms. These systems analyze color histograms, textures, and pattern properties to grade stones with 69.4% accuracy on unseen gemstone images.

Remarkably, expert gemmologists achieved only 42.6-66.9% accuracy on the same stones while taking significantly longer (42-175 minutes versus 0.0165 seconds for computer analysis). This suggests AI may soon surpass human expertise in certain grading applications.

Summary: The Future of Faceting

The technological revolution in faceting has transformed an ancient craft into a precision science. Computer-aided design eliminates guesswork, allowing cutters to predict light performance and color before making the first cut. Laser technology cuts diamonds 6 times faster than mechanical methods while achieving unprecedented precision. 3D scanning reduces waste by two-thirds, and robotic systems can process 50,000 small gems daily.

Key technological advances include:

- CAD software that predicts light performance and color before cutting

- Femtosecond lasers that cut diamonds as easily as soft metals

- 3D scanning that identifies optimal cut patterns and reduces waste

- Automated systems that complete in 27 minutes what once took 87 minutes

- AI grading systems that analyze gems faster and more accurately than human experts

These advances don't replace human artistry—they amplify it. Tomorrow's gem cutters will combine traditional craftsmanship with digital precision, creating stones of unprecedented beauty and perfection. The ancient art of revealing fire within stone has never been more exciting or full of possibility.

International Gem Society

Never Stop Learning

When you join the IGS community, you get trusted diamond & gemstone information when you need it.

Get Gemology Insights

Get started with the International Gem Society’s free guide to gemstone identification. Join our weekly newsletter & get a free copy of the Gem ID Checklist!