Introduction to Faceting Mini Course

Hardness and Cleavage Considerations

Picture this: You're holding a stunning piece of rough diamond, the hardest material on Earth. You strike it with a hammer, expecting it to resist. Instead, it shatters into a dozen pieces. Meanwhile, a piece of jade—much softer—rings like a bell under the same blow. This surprising reality reveals a crucial truth about gemstone cutting: hardness doesn't tell the whole story.

Successfully cutting and faceting gemstones requires understanding two critical properties that can make or break your project—literally. Hardness determines how easily a stone scratches, while cleavage controls how it breaks. These properties work together in complex ways that challenge even experienced gem cutters.

The difference between a beautiful finished gem and a pile of expensive fragments often comes down to understanding these fundamental characteristics. Even household dust, containing quartz particles, can scratch gems softer than 7 on the Mohs scale. This means your beautiful opal ring might lose its polish just from everyday cleaning.

In this article, you'll learn:

- How the Mohs scale impacts cutting strategies and equipment choices

- Why diamonds can shatter despite being the hardest gemstone

- Which stones require special handling techniques to avoid catastrophic failure

- How cleavage planes determine cutting orientation and success rates

- Practical tips for working with challenging materials like spodumene and fluorite

The Mohs Scale and Its Impact on Cutting

Understanding the Mohs Hardness Framework

The Mohs hardness scale, created by German mineralogist Friedrich Mohs in 1812, remains the gem cutter's most essential tool. This scale ranks minerals from 1 (talc) to 10 (diamond) based on their scratch resistance. However, the scale hides a crucial secret that trips up many beginners.

The Mohs scale isn't linear—it's dramatically skewed toward the top. While corundum (sapphire and ruby) ranks 9 and diamond ranks 10, diamond is actually four times harder than corundum. This massive jump explains why diamond cutting requires completely different techniques and equipment than any other gemstone.

Understanding this scale helps explain why certain thresholds matter so much. Gems below 7 face constant danger from household dust, which contains quartz particles. This is why opals and pearls, despite their beauty, require careful handling and protective settings in jewelry.

The Critical Hardness 7 Threshold

The number 7 on the Mohs scale represents more than just a ranking—it's a survival line for gemstones. Quartz, which rates 7 to 7.5, makes up a significant portion of household dust. This means any gemstone softer than quartz will gradually lose its polish through normal exposure to dust particles.

Even routine cleaning becomes dangerous for softer stones. Wiping dust off furniture can scratch gems like moonstone (6) or turquoise (5-6). This reality forces gem cutters to consider not just the beauty of their finished stones, but their long-term durability in real-world conditions.

Professional cutters use this knowledge to guide their advice to customers. A stunning fluorite pendant might be perfect for special occasions, but a fluorite engagement ring would be a disaster waiting to happen.

Cutting Challenges Across Hardness Levels

Hard Gemstones (8-10 on Mohs Scale)

The hardest gemstones present unique challenges that seem counterintuitive. Diamond, despite its legendary hardness, requires diamond-impregnated cutting wheels and extensive time to shape. The cutting process exploits directional hardness variations—diamond is actually easier to cut in certain directions than others.

Sapphires and rubies (corundum) at hardness 9 demand specialized aluminum oxide wheels and careful heat management. These stones can handle aggressive cutting but require patience. A single facet might take several minutes to polish properly.

Medium-Hard Gemstones (6-8 on Mohs Scale)

This sweet spot includes popular stones like quartz, beryl, and topaz. These materials offer the best balance of workability and durability. Standard faceting equipment handles them well, and cutting angles have been optimized through decades of experience.

However, even in this range, surprises await. Topaz's perfect cleavage can cause sudden, catastrophic splits if cutters aren't careful about orientation. The material cuts beautifully until it doesn't—then it's gone.

Soft Gemstones (2-6 on Mohs Scale)

Soft gemstones require specialized techniques and extraordinary patience. Materials like fluorite (4) and turquoise (5-6) can crumble under normal cutting pressure. Success depends on using lighter touch, frequent cooling, and often pre-treating porous materials with stabilizing agents.

These materials often produce the most dramatic colors and optical effects, making the extra effort worthwhile. However, the high failure rate means cutters must factor significant material loss into their calculations.

Directional Hardness: The Hidden Variable

One of the most sophisticated aspects of gem cutting involves directional hardness variations. Many crystals exhibit different hardness depending on which direction you cut them. Kyanite provides an extreme example—it measures 5 on one axis but 7 on the perpendicular axis.

This phenomenon affects cutting strategy dramatically. Diamond cutters carefully orient rough stones to take advantage of easier cutting directions while avoiding the hardest orientations. Getting this wrong can turn a profitable cutting project into an expensive lesson.

Even experienced cutters sometimes discover directional hardness the hard way. A stone that cuts easily in one direction suddenly becomes impossible to polish when approached from a different angle.

Stones That Require Special Handling

The Cleavage Challenge: When Hard Doesn't Mean Tough

Cleavage represents one of the most dangerous aspects of gem cutting. Unlike fractures, which break randomly, cleavage follows predictable planes of weakness in the crystal structure. Understanding cleavage grades helps predict cutting challenges:

- Perfect cleavage: Splits easily with minimal force

- Good cleavage: Breaks with moderate pressure

- Fair cleavage: Offers some resistance to splitting

- Poor cleavage: Difficult to split along planes

- No cleavage: Maximum resistance to splitting

Diamond: The Hardest Paradox

Diamond exemplifies the difference between hardness and toughness. While nothing can scratch diamond, it has perfect cleavage in four directions. This means a steel hammer, which can't scratch diamond, can shatter it completely.

Professional diamond cutters exploit this cleavage for initial shaping, using precise strikes to split rough diamonds along cleavage planes. However, finished stones must be oriented carefully to avoid placing table facets parallel to cleavage planes, which would create vulnerable spots.

The diamond cutting industry developed around understanding this paradox. Traditional cleaving techniques use these weakness planes advantageously, while modern sawing avoids them entirely.

Topaz: The Beautiful Trap

Topaz presents one of the most deceptive cutting challenges in gemology. With hardness 8, it seems robust enough for any application. However, its perfect cleavage plane perpendicular to the c-axis makes it surprisingly fragile.

Experienced cutters orient topaz rough at least 7-10 degrees away from the cleavage plane when positioning the table facet. Commercial cutters sometimes use the natural cleavage surface as the table to save labor, but this compromises both optical performance and durability.

The cleavage plane in topaz appears as parallel terracing effects on crystal faces. Learning to identify these warning signs prevents costly mistakes during the cutting process.

Spodumene (Kunzite): The Heartbreak Stone

Spodumene, including the popular variety kunzite, poses extraordinary challenges for cutters. Perfect cleavage planes running parallel to the c-axis, combined with extreme fragility, make this material unpredictable and dangerous to work with.

Stories abound of valuable spodumene rough worth thousands of dollars developing spontaneous fractures during cutting, resulting in complete loss. Even gentle handling can trigger catastrophic failure if stress concentrates along cleavage planes.

Successful spodumene cutting requires placing cleavage planes at the girdle rather than parallel to the table. Oval or cushion shapes work best, as girdle facets can avoid direct alignment with cleavage planes.

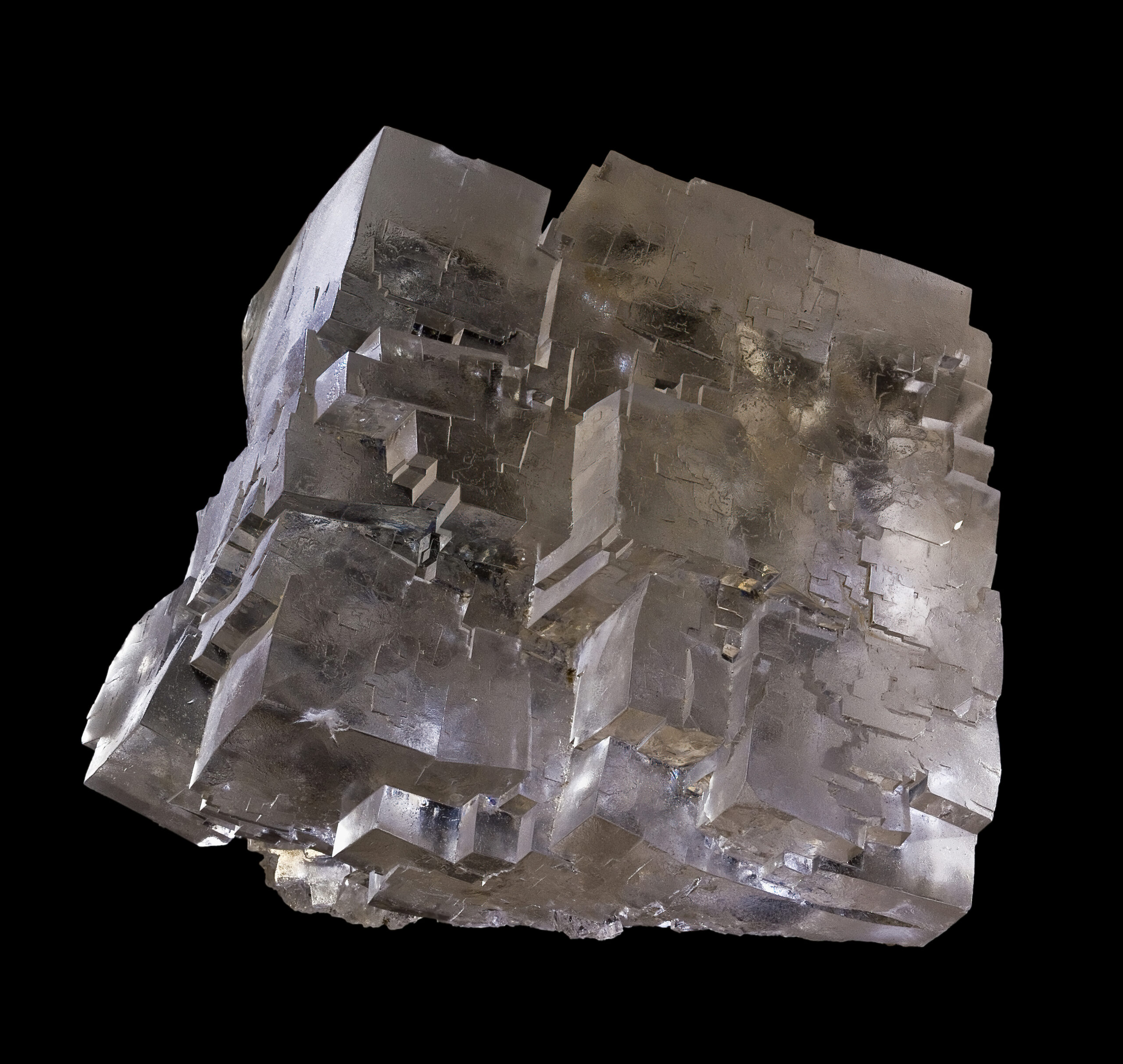

Fluorite: The Multi-Challenge Material

Fluorite combines multiple cutting difficulties into one deceptively pretty package. With hardness 4, perfect cleavage in four directions, and high heat sensitivity, it tests every aspect of a cutter's skill.

The material requires table orientation approximately 10 degrees off crystal faces to minimize cleavage problems. Heat buildup during cutting can cause thermal expansion and cracking, so frequent cooling breaks are essential.

Despite these challenges, fluorite's exceptional optical properties and vivid colors make it worth the effort for collectors and specialty applications.

Emerald: Managing the Jardin

Emerald cutting involves navigating characteristic inclusions called "jardin" (French for garden) while managing the material's moderate hardness and susceptibility to fractures. These inclusion patterns require cutters to carefully assess each stone's internal structure.

The extensive inclusions actually help in some ways—they can arrest crack propagation and provide visual guides for orientation. However, they also create stress concentration points that can lead to sudden failure.

Emerald cutting often employs low-impact techniques and specialized pre-forming to remove stress points before faceting begins. Success requires balancing inclusion management with structural integrity.

Organic Materials: Special Cases

Turquoise: The Porous Challenge

Turquoise's high porosity and minimal crystal symmetry create unique cutting problems. The material's tendency to crumble requires water soaking for higher-quality specimens and super glue treatment for porous materials.

The lack of symmetry in turquoise's crystal structure makes it unpredictable during cutting. What works on one section of a stone might fail completely on another part of the same specimen.

Pearls: Layered Complications

Pearl cutting requires understanding the distinction between nucleus and nacre layers. Some pearls have nuclei that aren't fixed and can "roll" during cutting, creating unexpected challenges.

The technique involves careful securing with tape and using low-RPM separating discs with frequent water cooling. Chinese freshwater pearls prove easier to cut due to their tissue nucleation without hard shell bead nuclei.

Jade: The Tough Survivor

Despite moderate hardness (6-7), jade's exceptional toughness due to its interlocked polycrystalline structure requires specialized approaches. Traditional jade cutting uses harder abrasives with constant water cooling to prevent thermal cracking.

The fibrous structure that gives jade its legendary toughness also makes it resistant to conventional cutting methods. This explains why jade can survive hammer blows that would shatter much harder materials.

Modern Solutions and Equipment

Contemporary gem cutting employs specialized equipment adapted to challenging materials. Black diamonds require diamond-impregnated wheels with coarser powder due to their maze-like fracture patterns. Fantasy cuts and concave faceting use three-dimensional cutting tools impossible with traditional flat laps.

Safety considerations become critical when working with challenging materials. Proper ventilation, dust masks, and eye protection are essential when cutting materials that generate harmful particles.

Summary

Understanding hardness and cleavage forms the foundation of successful gemstone cutting. While the Mohs scale provides essential guidance, the reality involves mastering complex interactions between crystal structure, directional properties, and material-specific vulnerabilities.

The most important lesson is that hardness alone doesn't determine cutting difficulty. Diamond's hardness makes it scratch-resistant, but its perfect cleavage makes it surprisingly fragile. Conversely, jade's moderate hardness belies its exceptional toughness due to structural factors.

Key takeaways for successful gem cutting:

- Hardness below 7 means vulnerability to dust damage and special handling requirements

- Perfect cleavage can make even the hardest materials fragile and unpredictable

- Directional hardness variations require careful orientation planning

- Heat sensitivity and porosity add layers of complexity beyond hardness considerations

- Specialized equipment and techniques are essential for challenging materials

- Understanding material properties prevents costly failures and maximizes success rates

Success in gem cutting comes from respecting these fundamental properties and adapting techniques accordingly. Whether working with the hardest diamond or the most fragile fluorite, understanding how hardness and cleavage interact determines the difference between a masterpiece and expensive rubble.

International Gem Society

Never Stop Learning

When you join the IGS community, you get trusted diamond & gemstone information when you need it.

Get Gemology Insights

Get started with the International Gem Society’s free guide to gemstone identification. Join our weekly newsletter & get a free copy of the Gem ID Checklist!