Introduction to Faceting Mini Course

Cut Grading Systems: The Professional Standard for Diamond Craftsmanship

As a gem cutter, your skill determines whether a rough diamond becomes a brilliant masterpiece or an unremarkable stone. Every angle you cut, every facet you polish, and every proportion you achieve directly impacts how gemologists will grade your finished work. Understanding cut grading systems isn't just academic knowledge—it's the foundation of your craft and your reputation.

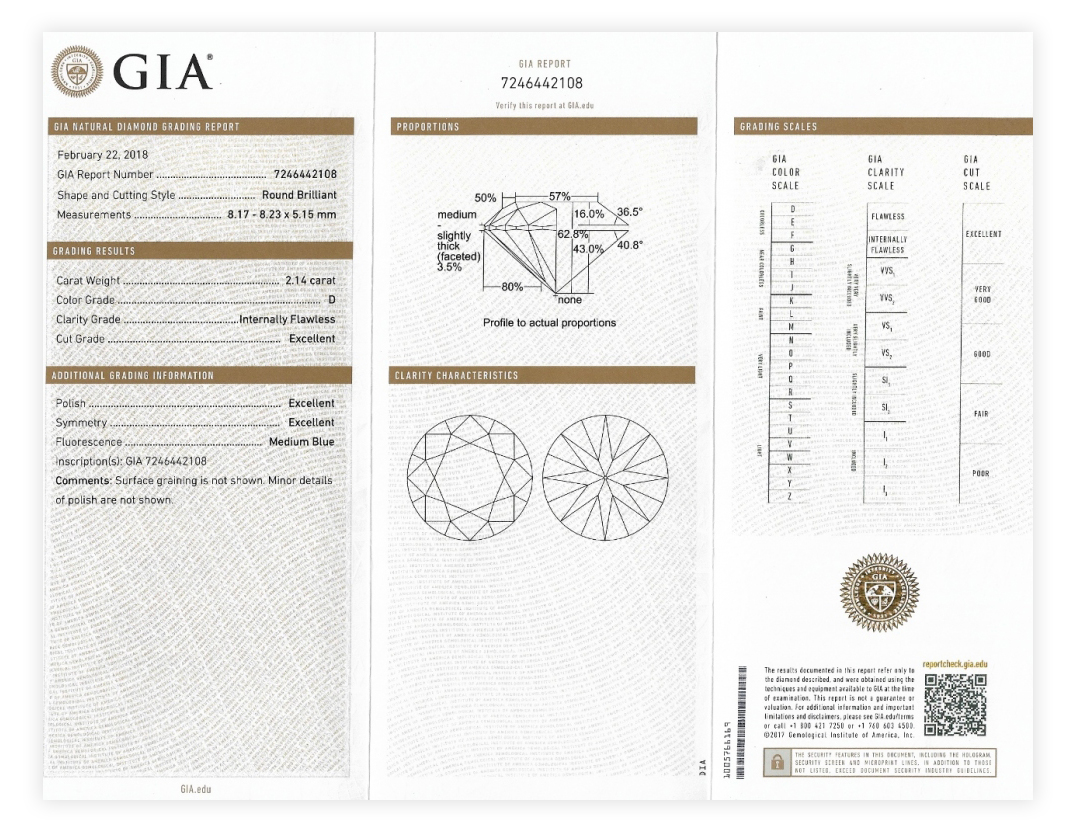

The GIA cut grading system represents the industry standard that evaluates your technical expertise and artistic vision. This system measures how successfully you've transformed rough material into a light-performing gem. Your cutting decisions directly influence whether a stone receives an Excellent grade or falls into lower categories.

Mastering these grading criteria elevates your work from adequate to exceptional. Professional cutters who understand these standards consistently produce higher-value stones and build stronger reputations in the industry.

In this article, you'll master:

- How the GIA cut grading system evaluates your craftsmanship

- The technical requirements for achieving each of the five cut grades

- Critical symmetry, polish, and proportion standards you must meet

- How measurement tolerances affect your finished stones' grades

- Professional techniques for optimizing cut quality and maximizing value

The Professional Evolution of Cut Standards

From Craftsman Intuition to Scientific Precision

Before 1950, diamond cutting relied heavily on individual craftsman experience and traditional techniques passed down through generations. The GIA's Four Cs system introduced standardization, but early cut evaluation remained relatively simple and often inconsistent.

The original system classified cuts into four basic categories by measuring deviation from theoretical ideal proportions. This approach frustrated many skilled cutters whose beautiful stones received poor grades due to rigid mathematical standards that didn't account for visual performance.

The 2005 Game-Changer for Cutters

The 2005 GIA system revolutionized how your work is evaluated. Instead of penalizing deviation from ideal proportions, this system measures actual light performance. Your stones are now judged on how well they interact with light rather than conforming to rigid mathematical formulas.

This change benefits skilled cutters who understand light behavior. You can now achieve excellent grades through various proportion combinations, provided your cutting optimizes brightness, fire, and scintillation. The system rewards craftsmanship over formula adherence.

Understanding the Five Professional Grades

Excellent (EX): The Cutter's Gold Standard

Achieving Excellent requires mastering every aspect of your craft. These diamonds display maximum brilliance, scintillation, and perfectly balanced light-dark patterns. Your symmetry must be precise, polish flawless, and proportions optimized for light performance.

To consistently produce Excellent grades, you need exceptional technical skill and deep understanding of optical principles. Every facet angle, every surface finish, and every proportion relationship must work in harmony.

Very Good (VG): Professional Quality with Minor Compromises

Very Good stones demonstrate strong technical execution with minor limitations. These might show slight darkness in center areas or edge zones, or have pattern inconsistencies despite good brilliance and fire.

Sometimes material constraints force compromises that prevent Excellent grades. Weight retention requirements or inclusion avoidance might necessitate proportion adjustments that result in Very Good ratings despite excellent craftsmanship.

Good (G): Competent Work with Visible Limitations

Good grades typically result from proportion choices that prioritize weight retention over optical performance. These stones often appear darker around the girdle or show reduced scintillation compared to higher grades.

Weight ratio penalties frequently affect this category. When rough material economics require maximum carat retention, the resulting proportions may sacrifice light performance for commercial considerations.

Fair (F): Basic Cutting Standards

Fair grades indicate significant optical compromises. These stones show minimal brilliance or scintillation, often with pronounced dark areas around the girdle and table. While technically acceptable, they represent missed opportunities for better performance.

Economic pressures sometimes force cutting decisions that result in Fair grades. However, understanding the grading system helps you minimize performance loss even when working under constraints.

Poor (P): Substandard Cutting Execution

Poor grades reflect inadequate cutting technique or extreme material limitations. Common defects include "nail heads" (dark centers) and "fish eyes" (washed-out centers). These terms should never apply to professional work.

Many Poor grades result from excessive weight ratios rather than obvious visual defects. Understanding this relationship helps you balance weight retention with acceptable performance.

Technical Evaluation Criteria

The Seven Professional Standards

The GIA system evaluates seven components that directly reflect your cutting decisions and execution quality:

Visual Performance Criteria:

- Scintillation: The flashing light effects you create through facet arrangement and angle precision

- Pattern: The light-dark arrangement resulting from your internal and external reflection control

- Contrast: The relief between light and dark areas that creates visual appeal

Physical Execution Standards:

- Weight Ratio: How efficiently you've converted rough weight to polished diameter

- Durability: Your girdle thickness choices and inclusion management

- Polish: The surface quality you've achieved on every facet

- Symmetry: The precision of your facet alignment and shape execution

Why These Standards Matter to Your Work

Your lowest score among the first five factors determines the maximum possible grade. This means one weak area can prevent an otherwise excellent stone from achieving top rating. Understanding this helps you prioritize your cutting decisions.

Polish and symmetry receive separate evaluation but significantly influence the final grade. Poor execution in either area can downgrade an otherwise well-cut stone.

Mastering the Key Technical Factors

Symmetry: Precision Under Magnification

Professional symmetry evaluation examines your stone's outline accuracy, facet arrangement precision, pointing consistency, and table-culet centering. Every aspect reflects your technical control and attention to detail.

Modern grading uses measurement tolerances that require exceptional precision. Visual estimation isn't sufficient—your work must meet specific angular and dimensional standards. Investing in quality equipment and developing measurement skills directly impacts your grades.

Symmetry problems are often correctable during cutting. Recognizing potential issues early allows adjustments that prevent grade penalties. Regular evaluation during the cutting process helps maintain standards.

Polish: Surface Excellence on Every Facet

Professional polish evaluation examines every facet surface for scratches, nicks, chips, and other imperfections. Your polishing technique and wheel maintenance directly affect these grades.

Achieving excellent polish requires proper equipment, technique, and patience. Rushing the polishing process often creates defects that significantly impact the final grade. Understanding polishing wheel characteristics and maintaining optimal conditions ensures consistent results.

Even microscopic surface irregularities can affect light transmission and reduce grades. Professional-level polish requires examining your work under magnification and correcting any defects before completion.

Proportion: The Science of Light Optimization

Proportion mastery requires understanding how every dimensional relationship affects light performance. Your angle choices, depth percentages, and facet sizes must work together to optimize brilliance, fire, and scintillation.

Critical Dimensional Control

Diameter and Depth Management: Achieving consistent roundness requires careful material planning and execution. Total depth percentage directly affects light return—too shallow or deep significantly impacts performance.

Table Size Optimization: Your table size choice affects both brilliance and fire. Larger tables increase brilliance but reduce fire, while smaller tables do the opposite. Finding the optimal balance requires understanding the specific stone's characteristics.

Crown and Pavilion Angle Precision: These angles are the most critical proportion elements. Crown angles typically range from 34-35 degrees, while pavilion angles usually fall between 40.6-41.8 degrees. Small variations significantly impact light performance.

Star and Lower-Half Percentage Control: Star percentages typically range from 50-60%, while lower-half percentages usually fall between 75-80%. These proportions affect the stone's pattern and scintillation characteristics.

Girdle Thickness Balance: Your girdle must be thick enough for durability but not so thick that it adds excessive weight. Variations around the girdle should be minimized for optimal grading.

Culet Size Decisions: Modern preferences favor no culet or very small culets. Larger culets can create "windows" that reduce brilliance and negatively impact grades.

Professional Measurement Techniques

Precision Requirements

Modern cut grading requires measurements to the hundredth of a millimeter for many parameters. Your measuring equipment and technique must meet these precision standards to predict final grades accurately.

Using reticles with protractors for angle measurement ensures accuracy within required tolerances. Visual estimation techniques work for some parameters but require extensive experience to achieve professional accuracy.

Working with Facetware

The GIA's free Facetware application allows you to input your measurements and receive estimated grades. This tool helps you understand how your cutting decisions translate into final grades and identify areas for improvement.

Regular use of Facetware during your cutting process helps optimize your work before completion. Understanding which parameters most strongly influence the final grade guides your decision-making.

Maximizing Commercial Value Through Cut Quality

Economic Impact of Cut Grades

Cut grades directly affect the commercial value of your finished stones. Excellent cuts command significant premiums, while lower grades receive correspondingly lower prices. Understanding this relationship helps you make profitable cutting decisions.

The weight ratio factor can significantly impact grades even when stones appear beautiful. Balancing weight retention with optical performance requires understanding market preferences and client requirements.

Client Communication

Understanding cut grading helps you explain your work to clients and justify pricing. Being able to discuss specific grading criteria demonstrates professionalism and builds confidence in your expertise.

When clients request specific grades, understanding the requirements helps you assess feasibility and communicate any limitations or compromises that might be necessary.

Advanced Cutting Considerations

Material Optimization

Working with included material requires balancing inclusion removal with proportion optimization. Understanding how inclusions affect durability grades helps you make appropriate cutting decisions.

Sometimes removing inclusions through recutting can improve overall grades despite weight loss. Understanding the grade impact helps evaluate whether recutting is economically justified.

Fancy Shape Applications

While GIA cut grades currently apply only to round brilliants, the principles inform quality standards for fancy shapes. Understanding light performance optimization helps you produce better fancy cuts even without formal grading systems.

Research continues on expanding cut grading to other shapes. Staying current with developments positions you for future market changes.

Professional Development Through Grading Knowledge

Skill Assessment

Understanding grading criteria helps you honestly assess your current skill level and identify areas for improvement. Comparing your work to grading standards reveals specific technical weaknesses to address.

Regular grade tracking of your finished stones provides objective feedback on your progress and consistency. Maintaining records helps identify patterns and improvement opportunities.

Continuous Improvement

The grading system provides a roadmap for skill development. Working systematically to improve each grading factor develops well-rounded cutting expertise.

Focusing on your weakest grading areas typically provides the greatest improvement in overall grades and commercial value.

Summary: Professional Excellence Through Understanding

The GIA cut grading system provides the professional standard for evaluating your craftsmanship. By understanding how symmetry, polish, and proportion combine to affect light performance, you can consistently produce higher-quality stones that command premium prices.

Proficiency benefits include:

- Objective standards for evaluating and improving your cutting technique

- Understanding of how specific cutting decisions affect commercial value

- Ability to communicate professionally about cut quality with clients

- Framework for systematic skill development and quality improvement

- Knowledge of industry standards that affect your reputation and success

Mastering cut grading systems transforms you from a competent cutter into a true professional. Your understanding of these standards directly translates into better stones, higher prices, and enhanced reputation in the industry. Every stone you cut is an opportunity to demonstrate your expertise and commitment to excellence.

International Gem Society

Never Stop Learning

When you join the IGS community, you get trusted diamond & gemstone information when you need it.

Get Gemology Insights

Get started with the International Gem Society’s free guide to gemstone identification. Join our weekly newsletter & get a free copy of the Gem ID Checklist!